- +91-161-2848535

- info@alliedrecycling.in

- V.P.O Budhewal, Chandigarh Road, Ludhiana, Punjab

- CIN : U27100PB2003PLC026583

Our Other Products

Download Brochures

Contact Us

+91-161-2848535

Phone Number

info@alliedrecycling.in

Email Address

V.P.O Budhewal, Chandigarh Road, Ludhiana, Punjab

Office Address

Wire Rod

Wire rods play a crucial role in various industries. These versatile products are used in a wide range of applications, contributing to the production of high-quality mechanical and chemical properties.

One of the primary uses of wire rods is in industrial fasteners. From construction projects to manufacturing processes, wire rods ensure the durability and reliability of various structures and products. Auto components also benefit from the exceptional properties of wire rods. These components are vital for the automotive industry, ensuring the safety and efficiency of vehicles. Wire rods are used in the production of engine parts, suspension systems, and other critical components, contributing to the overall performance of automobiles on the road.

Moreover, wire rods are widely utilized in welding processes. Their high carbon grades and electrode grades make them ideal for creating strong and durable welds. Whether in construction, fabrication, or repair work, wire rods enable precise and efficient welding, ensuring the integrity and longevity of welded joints.

To summarise, wire rods are indispensable in various industries due to their exceptional properties. They are the backbone of industrial fasteners, auto components, and welding processes. Their high carbon grades and electrode grades make them reliable and efficient, guaranteeing the quality and durability of the final products.

Our industry is proud to present a diverse range of exceptional products, boasting an extensive selection of sizes, impeccable surface quality, and optimal design for seamless application and processing.

From the tiniest details to the grandest creations, we strive to deliver excellence in every aspect. Our commitment to producing top-notch products is evident in the rich line-up we offer, catering to various needs and preferences.

With an array of size variations available, we ensure that our products can be tailored to fit any requirement, providing flexibility and convenience for our valued customers.

Moreover, our unwavering dedication to surface quality guarantees a flawless finish that enhances the overall aesthetic appeal of our offerings.

Through our meticulous component control and cutting-edge rolling texture control techniques, we ensure that every product meets the highest standards for its intended application and processing requirements.

Our commitment to optimal component control guarantees that each part is precisely crafted, resulting in superior performance and durability. Additionally, our advanced rolling texture control allows us to tailor the surface finish of our products, providing enhanced functionality and aesthetics.

Size

6.0, 7.0, 8.0, 9.0, 10.0, 11.0, 12.0, 12.5, 13.3, 14.0, 15.0, 16.0, 17.3, 18.3, 19.0, 20.0, 21.0, 22.0, 23.0, 24.0, 25.0

Industry Implementations

- Electrode wires

- General purpose wires and rope wires

- Production of wire mesh

- Earth wires

- Vineyard wires

- Industrial wires and detonator wires

- Umbrella ribs

- Staple pin wires

- Springs, fasteners, bolts and chain rivet wires

- Needle wires and safety pin wires

- Hose reinforcement wires and cycle spokes

At our industry, we never settle for the present! We are constantly pushing the boundaries of product development to stay one step ahead and anticipate our customer’s needs in the future.

Our dedicated team of innovators and visionaries work tirelessly to create solutions that not only meet but exceed the expectations of our valued customers.

By staying ahead of the curve, we ensure that our customers are always equipped with the latest and most advanced technology, providing them with a competitive edge in their respective fields. We strive to be the pioneers, setting new standards and revolutionizing the way our industry operates.

Manufacturing Process Of Wire Rod

Step 1

Scrap Sorting

Step into the mesmerizing world of manufacturing, where the creation of billets is an awe-inspiring process!

It all starts with the humble scrap, ready to be transformed into something extraordinary.

By carefully examining and categorizing the scrap, we ensure that only the highest quality materials are chosen for our production. This not only guarantees the durability and strength of our billets but also minimizes waste and promotes a greener future.

Our dedicated team of experts works tirelessly to identify and separate different types of scrap, ensuring that each piece is utilized to its fullest potential. From aluminum to steel, we make sure that every material finds its purpose in our sustainable manufacturing process.

By incorporating recycled materials into our production, we reduce the need for extracting new resources, conserving energy and reducing carbon emissions.

Step 2

Chemical Analysis

Before our scrap materials are fed into the furnace, they go through a rigorous process of careful sorting and chemical analysis.

By subjecting our scrap to thorough chemical analysis, we ensure that only the highest quality materials are utilized in our recycling process. This not only guarantees the best possible results but also helps us minimize waste and maximize efficiency.

Step 3

Scrap Feeding

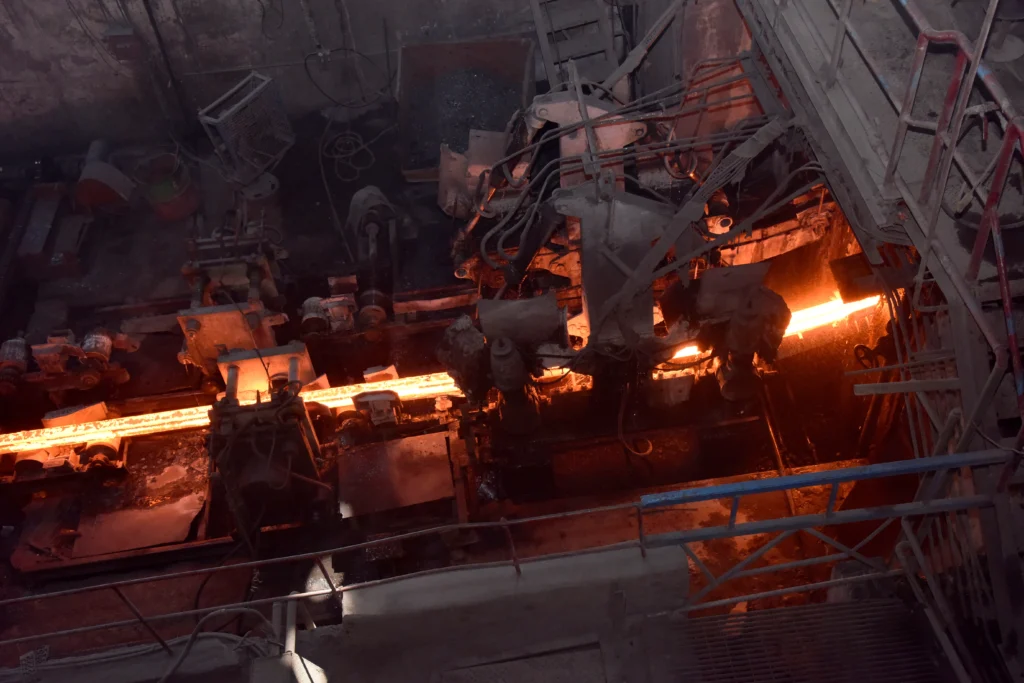

The scrap is carefully fed into the furnace, where an intense temperature of a scorching 1600 Degree Celsius is generated.

As the flames flicker, the scrap begins to melt down, undergoing a remarkable metamorphosis. It's a sight to behold as the once solid pieces transform into a molten liquid, brimming with potential and possibilities.

This fiery transformation is just the beginning! From here, the molten metal will be meticulously shaped and molded into billets, ready to be forged into various forms of strength and resilience.

Step 4

Chemical Addition

In the mesmerizing process of melting, impurities that cling to the surface of raw materials form a unique substance called slag. Our skilled hands meticulously remove this slag through manual labor, leaving behind pure molten metal ready for transformation!

And that's not all! To enhance the properties of the molten metal, we introduce Ferro Alloys, carefully selected to meet our desired specifications. These alloys bring a touch of magic, adding strength, resilience, and unique characteristics to the final product. From the fiery depths of our furnaces to the skilled hands of our workers, we strive to create the finest quality metal alloys that exceed expectations.

Step 6

Material Transfer From Furnace

As the temperature rises, the molten metal reaches its perfect melting point, ready to be transformed into magnificent billets.

With precision and expertise, the molten metal is poured into the Continuous Casting Machine (CCM), where it flows through copper mould tubes. These tubes act as a conduit, shaping the metal into solid billets.

The CCM works its magic, gradually cooling down the molten metal, solidifying it into sturdy billets. Once the cooling process is complete, the billet emerges, gleaming with strength and potential.

Step 8

Sizing In Required Length

The billet is then skillfully cut into the required lengths, ensuring it meets the specific needs of various industries. Then it is allowed to cool down before being sent for further inspection.

This intricate process combines artistry and engineering, creating the building blocks for countless structures and products. From skyscrapers to automobiles, these billets form the backbone of modern innovation.

Step 10

Visual Inspection & Testing

Each and every billet undergoes a meticulous visual inspection and rigorous testing process before it is considered a finished product.

Our dedicated team of experts ensures that every piece is carefully examined, guaranteeing the utmost quality and reliability.

Step 11

Finished Product Sorting

Our dedicated team of experts meticulously examines every detail, guaranteeing that our products meet the highest standards of quality and reliability. From functionality to durability, we leave no stone unturned in ensuring that our customers receive only the best.

Once this meticulous phase is completed, our products are sorted with utmost precision according to the inhouse requirement & orders.

Step 11

Continuous Rolling Process

Here the remarkable journey of a hot billet transforming into a perfectly sized wire rod through a continuous rolling process, takes place!

At our state-of-the-art rolling mill, the hot billet undergoes a series of meticulously controlled steps, ensuring its transformation into a high-quality wire rod of the desired size.

With precision and expertise, our skilled team guides the billet through the rolling mill, where it is shaped and elongated, gradually taking the form of a flawless wire rod.

This continuous process guarantees the utmost accuracy and consistency, resulting in wire rods that meet the exact specifications required for various applications.

Step 11

Cooling , Stacking & Dispatch

After undergoing the intense heat of production, our wire rod has successfully completed its transformation. It has been carefully cooled to reach its optimal state, ensuring its durability and strength.

Now, it's time for this magnificent wire rod to be stacked in lots according to its size. Once they've reached the perfect temperature, they are carefully stacked in neat lots, sorted by size and ready for their next adventure. These Wire Rods are ready to be dispatched and conquer new horizons. Each bundle represents the culmination of our hard work and dedication, ready to be dispatched to fulfill its purpose.

From the scorching furnaces to the cool breeze, this wire rod has truly gone through a remarkable journey. We take pride in delivering the highest quality products to our valued customers, and this wire rod is no exception.

we take immense pride in our unwavering commitment to delivering top-notch quality in everything we do. Our dedication to excellence has been the cornerstone of our ongoing success, making our services and products highly sought-after in the market.

From the very beginning, we have never compromised on the quality of our recycling processes and services. Our state-of-the-art facilities, cutting-edge technology, and highly skilled team ensure that every step of our recycling journey is executed with precision and care.

By upholding the highest standards of quality, we have not only gained the trust and loyalty of our valued customers but have also established ourselves as a leader in the industry.

©2024. Allied Group. All Rights Reserved.

Design & Developed By Blitz Communications