- +91-161-2848535

- info@alliedrecycling.in

- V.P.O Budhewal, Chandigarh Road, Ludhiana, Punjab

- CIN : U27100PB2003PLC026583

Our Other Products

Download Brochures

Contact Us

+91-161-2848535

Phone Number

info@alliedrecycling.in

Email Address

V.P.O Budhewal, Chandigarh Road, Ludhiana, Punjab

Office Address

Steel Billet

With immense pride, we present to you our cutting-edge facility, equipped with four advanced induction furnaces and a remarkable continuous casting machine. At our facility, quality is our top priority! Our highly trained personnel meticulously control the production process through continuous testing and process control. This ensures that every billet and bloom we produce meets the highest standards of excellence.

We take pride in offering a wide range of special steel grades, adhering to the strict guidelines set by esteemed organizations such as IS, BIS, DIN, and SAE Standards.

With a reputation for excellence and a commitment to delivering the highest quality products, Allied Recycling Limited is your go-to destination for all your metal alloy needs. Our extensive range of metal alloy ingots and billets is carefully crafted to meet the diverse requirements of various industries. Whether you’re in the automotive, aerospace, or construction sector, we have the perfect solution for you. Allied Recycling Limited is proud to be one of the leading Metal Billets manufacturers, dedicated to serving the market with utmost diligence.

Billet Size Range

BILLET / BLOOM : 125 x 125 mm

Major Steel Grades

- Low Carbon Steel SAE 1008, C20, CLII, Ai05

- Plain Carbon Steel EN8D, EN42, C30, C40, C45, C50

- Carbon Manganese Steel EN 15, 37C15, SAE 1541

- Free Cutting Steel EN 1A, SAE 1118, SAE 1140

- Ni, CR, MO SAE8620, SAE8622, EN353, EN24, 637H 17

- Chrome Manganese Steel 16MnCr5, 20MnCr5, EN 18

- Chrome Moly Steel EN 19, SAE 4140, SCM 415

- Ball Bearing Steel SAE 52100

- Chrome Vanadium Steel 31 CrV3

- Spring Steel EN 45A, 65Si7, SUP 11A, SUP 9, 55Si7, EN47, En48

Supply Length: Maximum length up to 9 meters.

Mechanical Properties: Conforming to customer’s requirement and as per ASTM / BIS / SAE.

Product Identification: Billets are identified by color coding across the section surface of each billet with reference to heat number and grade.

Test Certificate: Test Certificates are issued from our in-house testing Lab, by product specification as required by the customer.

Product Applications: Our carbon & alloy steel products have extensive application in automotive, engineering and forging industries.

With years of experience and expertise in the industry, we have perfected the art of producing high-quality metal billets that meet the highest standards.

Whether you need standardized or customized specifications, we’ve got you covered! Our team of experts is committed to tailoring our products to match your unique needs, ensuring a seamless fit for your projects.

Join the league of satisfied clients who have experienced the magnificence of our fame firsthand! Please place your order with us today and witness the unrivaled quality and reliability that sets us apart.

Manufacturing Process Of Billets

Step 1

Scrap Sorting

Step into the mesmerizing world of manufacturing, where the creation of billets is an awe-inspiring process!

It all starts with the humble scrap, ready to be transformed into something extraordinary.

By carefully examining and categorizing the scrap, we ensure that only the highest quality materials are chosen for our production. This not only guarantees the durability and strength of our billets but also minimizes waste and promotes a greener future.

Our dedicated team of experts works tirelessly to identify and separate different types of scrap, ensuring that each piece is utilized to its fullest potential. From aluminum to steel, we make sure that every material finds its purpose in our sustainable manufacturing process.

By incorporating recycled materials into our production, we reduce the need for extracting new resources, conserving energy and reducing carbon emissions.

Step 2

Chemical Analysis

Before our scrap materials are fed into the furnace, they go through a rigorous process of careful sorting and chemical analysis.

By subjecting our scrap to thorough chemical analysis, we ensure that only the highest quality materials are utilized in our recycling process. This not only guarantees the best possible results but also helps us minimize waste and maximize efficiency.

Step 3

Scrap Feeding

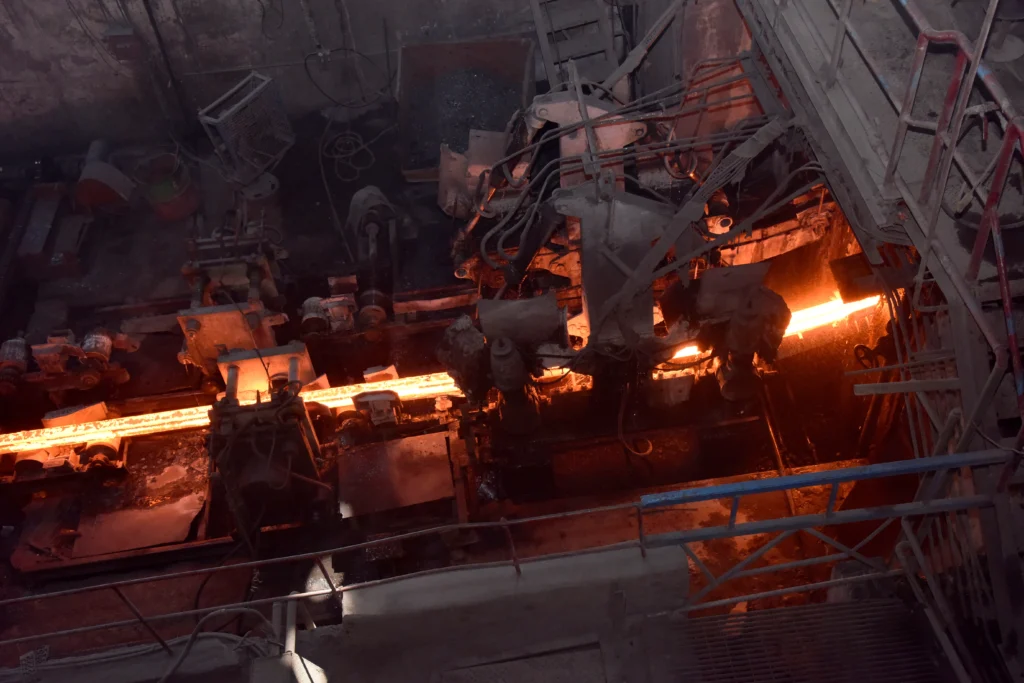

The scrap is carefully fed into the furnace, where an intense temperature of a scorching 1600 Degree Celsius is generated.

As the flames flicker, the scrap begins to melt down, undergoing a remarkable metamorphosis. It's a sight to behold as the once solid pieces transform into a molten liquid, brimming with potential and possibilities.

This fiery transformation is just the beginning! From here, the molten metal will be meticulously shaped and molded into billets, ready to be forged into various forms of strength and resilience.

Step 4

Chemical Addition

In the mesmerizing process of melting, impurities that cling to the surface of raw materials form a unique substance called slag. Our skilled hands meticulously remove this slag through manual labor, leaving behind pure molten metal ready for transformation!

And that's not all! To enhance the properties of the molten metal, we introduce Ferro Alloys, carefully selected to meet our desired specifications. These alloys bring a touch of magic, adding strength, resilience, and unique characteristics to the final product. From the fiery depths of our furnaces to the skilled hands of our workers, we strive to create the finest quality metal alloys that exceed expectations.

Step 6

Material Transfer From Furnace

As the temperature rises, the molten metal reaches its perfect melting point, ready to be transformed into magnificent billets.

With precision and expertise, the molten metal is poured into the Continuous Casting Machine (CCM), where it flows through copper mould tubes. These tubes act as a conduit, shaping the metal into solid billets.

The CCM works its magic, gradually cooling down the molten metal, solidifying it into sturdy billets. Once the cooling process is complete, the billet emerges, gleaming with strength and potential.

Step 8

Sizing In Required Length

The billet is then skillfully cut into the required lengths, ensuring it meets the specific needs of various industries. Then it is allowed to cool down before being sent for further inspection.

This intricate process combines artistry and engineering, creating the building blocks for countless structures and products. From skyscrapers to automobiles, these billets form the backbone of modern innovation.

Step 10

Visual Inspection & Testing

Each and every billet undergoes a meticulous visual inspection and rigorous testing process before it is considered a finished product.

Our dedicated team of experts ensures that every piece is carefully examined, guaranteeing the utmost quality and reliability.

Step 11

Finished Product Sorting & Dispatch

Our dedicated team of experts meticulously examines every detail, guaranteeing that our products meet the highest standards of quality and reliability. From functionality to durability, we leave no stone unturned in ensuring that our customers receive only the best.

Once this meticulous phase is completed, our products are sorted with utmost precision according to the requirement & orders. Our skilled professionals carefully organize and package each item, making sure that it reaches its destination as per requirement in perfect condition.

We understand the importance of timely delivery, and that's why we prioritize efficient dispatching. Our logistics team works tirelessly to ensure that your orders are promptly shipped and reach you as quickly as possible.

we take immense pride in our unwavering commitment to delivering top-notch quality in everything we do. Our dedication to excellence has been the cornerstone of our ongoing success, making our services and products highly sought-after in the market.

From the very beginning, we have never compromised on the quality of our recycling processes and services. Our state-of-the-art facilities, cutting-edge technology, and highly skilled team ensure that every step of our recycling journey is executed with precision and care.

By upholding the highest standards of quality, we have not only gained the trust and loyalty of our valued customers but have also established ourselves as a leader in the industry.

©2024. Allied Group. All Rights Reserved.

Design & Developed By Blitz Communications